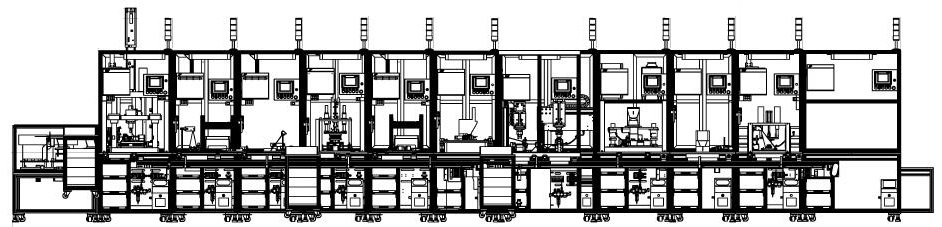

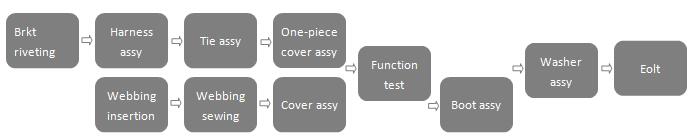

This buckle finishing assembly line consists of 11 workstations, detail process is as below, to achieve buckle finish assembly. The whole line cycle time is 12 seconds per part. There are totally 5 types of products for both front row and rear row.

For hardware of the line, LVDT is used to measure rivet height, TOX cylinder to riveting, automatic bowl feeder to load rivets, brother sewing machine to sewing and cutting thread automatically, Keithley source meter to measure current and resistance, visual camera for poka yoke, etc..

As for control system, SIEMENS PLC is used, cooperating with workshop traceability system, to ensure every product from the line is traceable.

Boaosi automation, aiming to offer customer a whole set of automation solution!